Hard Metal

explore

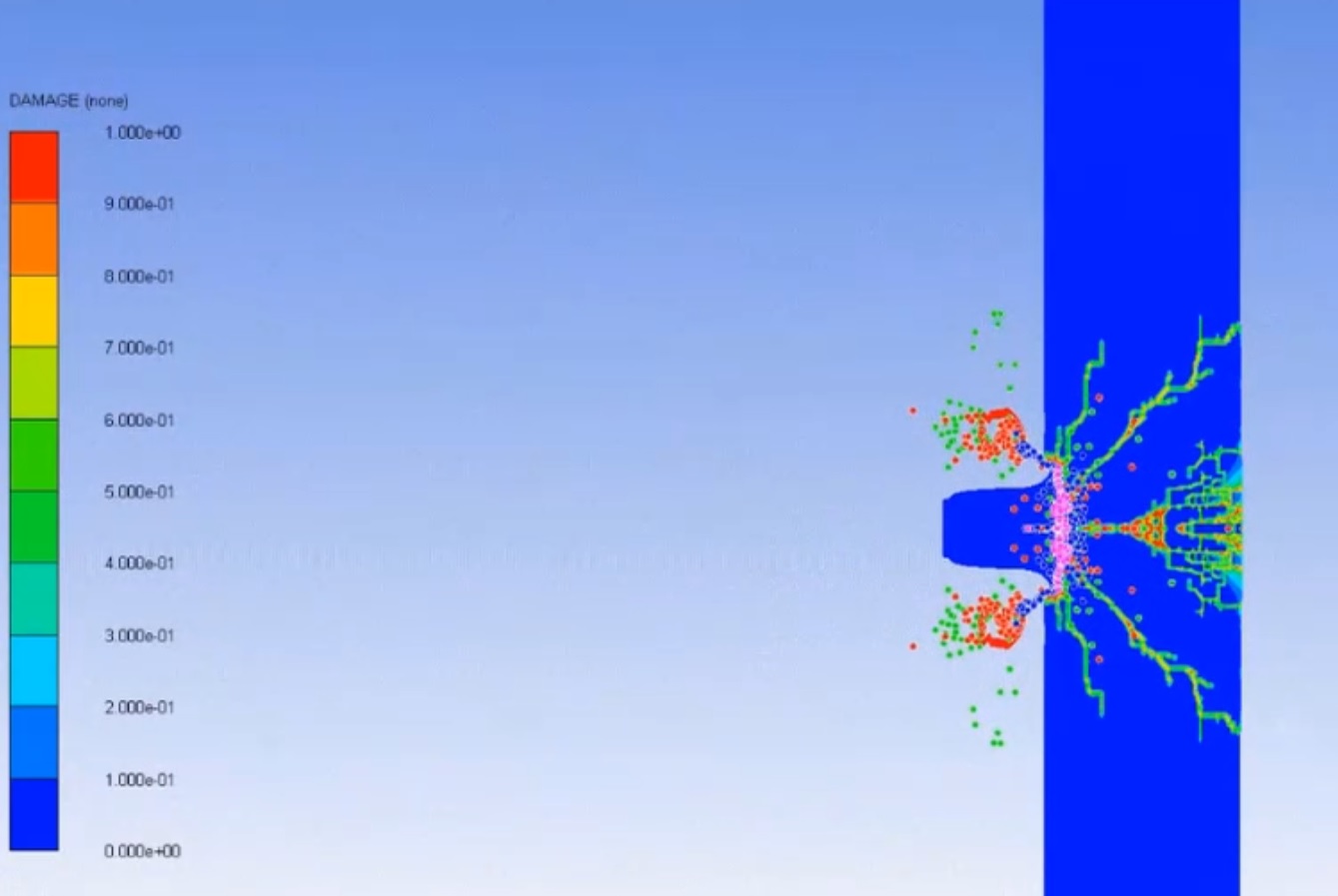

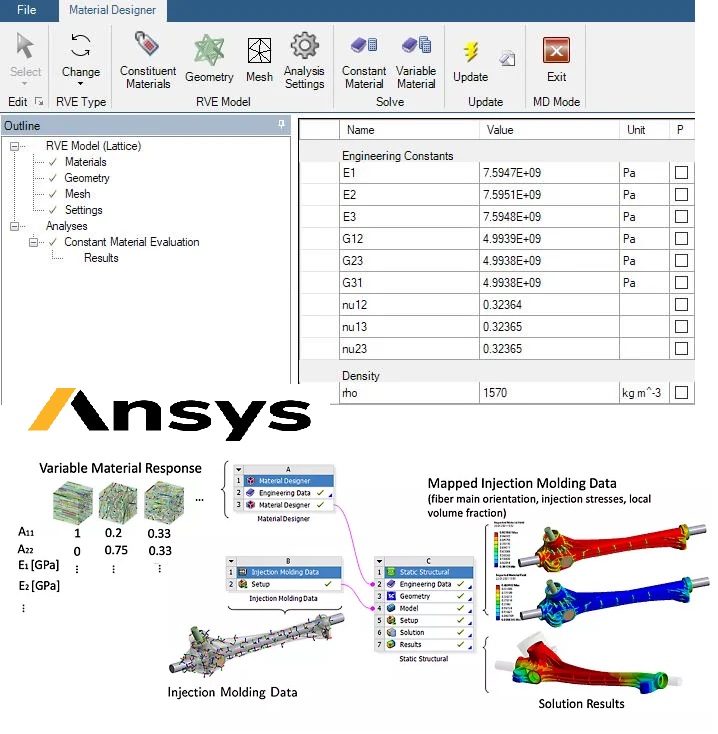

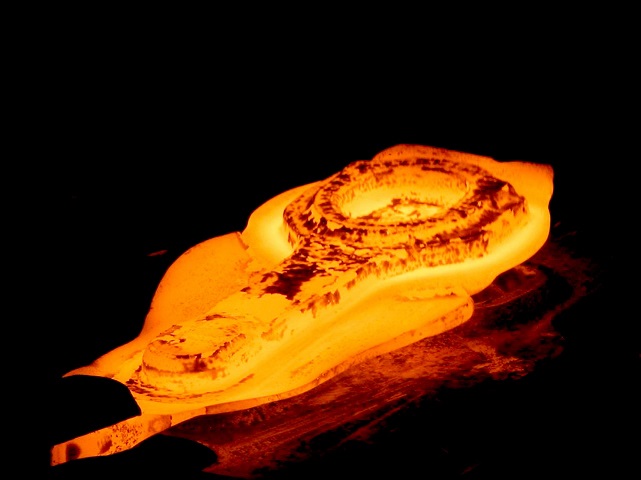

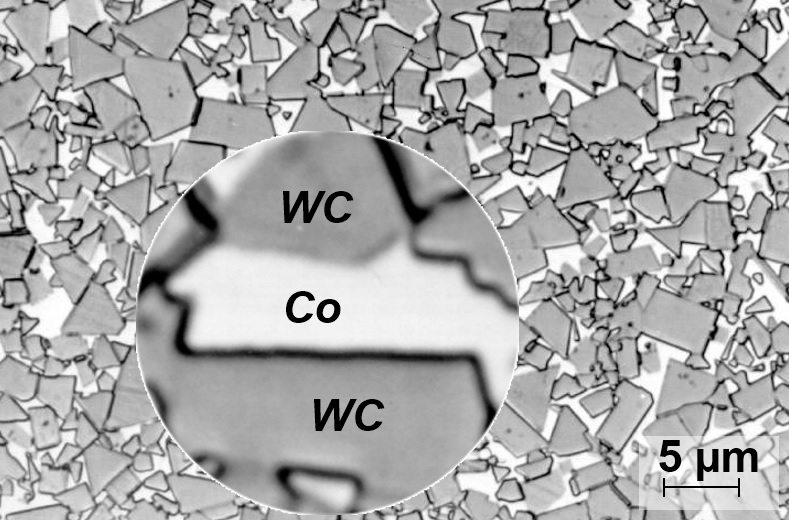

Hard metals, also known as cemented carbides, are composite materials that are made up of a metal matrix and a hard ceramic phase. The metal …

Discover More